Factory

Ledoauto has been in the business of automotive lighting since 2012. We’ve been moving a lot of our clients from HID industry to the LED marketplace, currently designing and Manufacturing LED lights for 12 Volt automotive lights and 24 Volt truck lights, for LED headlight kits, tail lights, parking lights, turn signal lights, reverse lights and

interior lights.

We have three manufacture workshop respectively located on Guangzhou Shi, Zhongshan Shi and Dongguan Shi and get about 10000 square meters production area, over 300 skillful employees. What’s really important is all our staffs go through that training and certification to make sure they are capable of their works.

Now we possess 16 operating production line for led headlight and 4 operating production line for led bulb. Everyone is equipped with the advanced technology and facilities. As long as a new product is put into production, it can be mass-produced immediately.

Automation is the backbone of our manufacturing. Each of our automation lines includes laser, etch solder stenciling component pick-and-place and Reflow soldering, the end of each of those assembly lines uses automated optical inspection to inspect every component in every solder joint on every sembly we produce.

We have a humidity controlled ESD safe environment here. It’s very important that we protect the products from static discharge. So we have an ESC tile floor. We have all new equipment for plates in the side or in the components in for reflow and for the Aoi infection at the end, we pay close attention to the maintenance of our stencils. And we also do solder paste inspection where necessary to give you an idea of how small parts are we can play.

We do the performance tested and torture tested for longevity in this room.

This spectroradiometer is for testing the light output of an individual LED chip.

In the salt spray test chamber, we test the aluminum components. Every piece of aluminum is tested for corrosion. One day in salt spray machine is equivalent to 6 months in the real world.

The constant temperature & humidity chamber is allowed to control the humidity. It can stimulate environments from negative 20 degrees right up at 50° C and humidity levels from 0 to 99%.

To test the light output of a led headlight bulb, we use another computer controlled integrating sphere. This one is 1.5 meters in diameter. Put the light bar in, close it up, and we get a highly accurate lumens rating.

For the UV tester, we put individual components in it to ensure that they gonna last in a tough sun irradiance. Each component is tested for its fade, its aging and potential crocking. The component will stay in the UV tester for 2 months, if they don’t pass the test, we will send back to the engineer for re-develop, re-design, new material, new coating, and then re-testing.

As a led headlight bulb is made, it’s also tested for an ip67 rating. This is the water-proof test chamber that actually pressure rises and then create a vacuum inside the housing to test for any leaks.

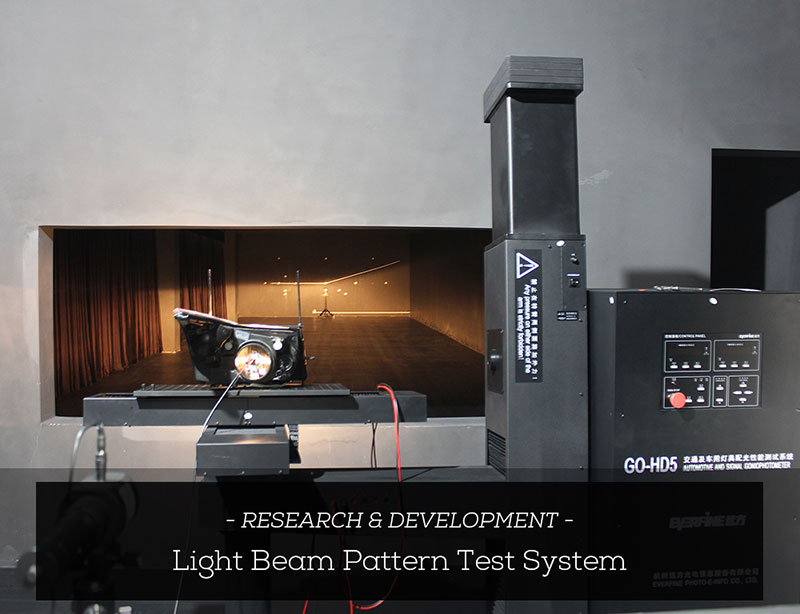

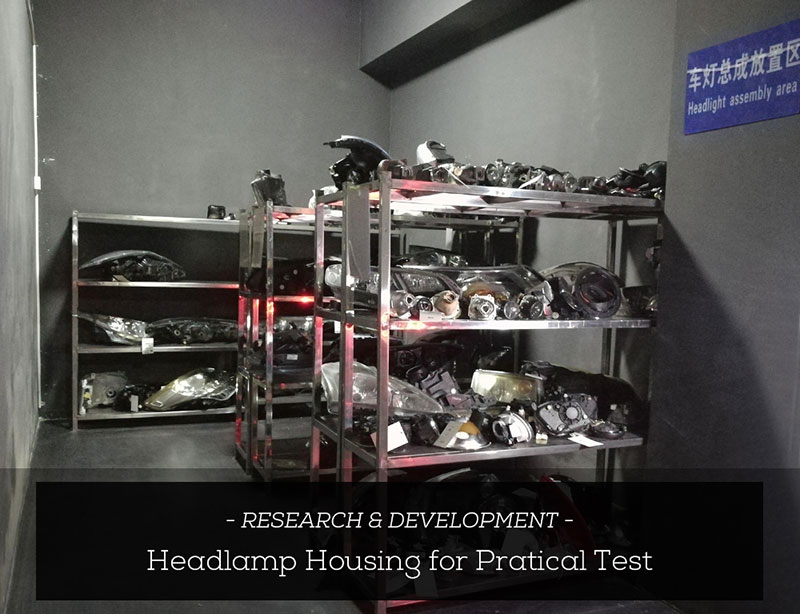

When designing the light distribution of the led headlight, we will use the light beam pattern test system and its optical design software. In the front of the test system, it is a dark room with 180 degrees of measurable space. We can accurately record the light spread and the lux on the wall and ground when we turn on the headlight. So we can improve at lumens and lux output of the led headlight for better performance and light beam pattern.

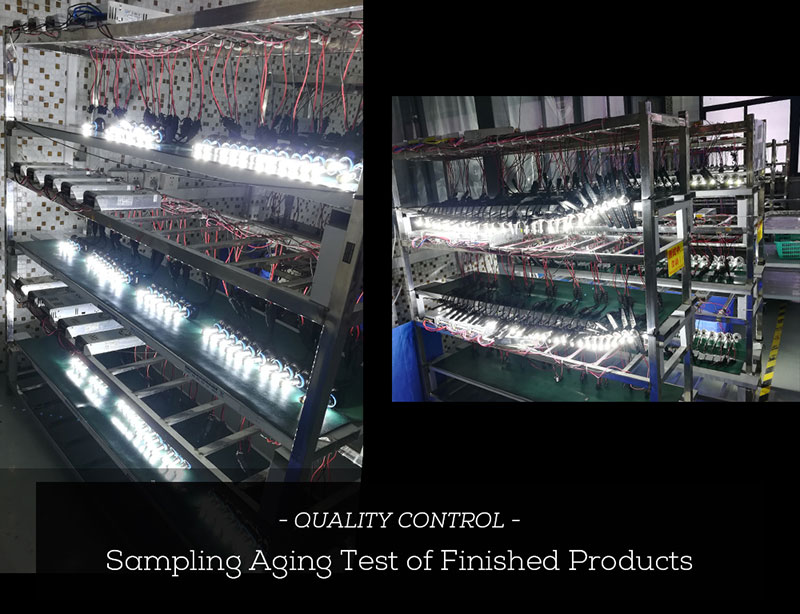

We have a strict quality control process from incoming raw material to finished good. Each product type has a different quality control standard to ensure they meet strict requirements. They mainly will experienced the four inspection stages below,

Incoming Quality Control – All incoming raw material are checked before used. Varies measurements are taken to check against approved data. Once rejected, raw material is sent back for further examination.

In Process Quality Control– We perform inspections during the manufacturing process. The frequency of inspection depends on the quality standard set forth by the project.

Final Quality Control – All finished goods are inspected according to our quality standard for each project. Products are sampled according to the AQL sampling rate before it leave our production plant into the warehouse.

Outgoing Quality Control – Our QC team will randomly check any finished goods in the warehouse before it goes out for shipment. This last inspection ensures zero defect goods are shipped to our customer.